Compact Ventilation Module

Variable, space-saving,

inexpensive.

Flexible bale ventilation modules without on-site measures.

Setting up and loading with front loader, yard loader or crane.

With one module 8 hay bales can be ventilated.

100-170 cm

Bale diameter

4 kW

Power

90-105 cm

Circle diameter

-

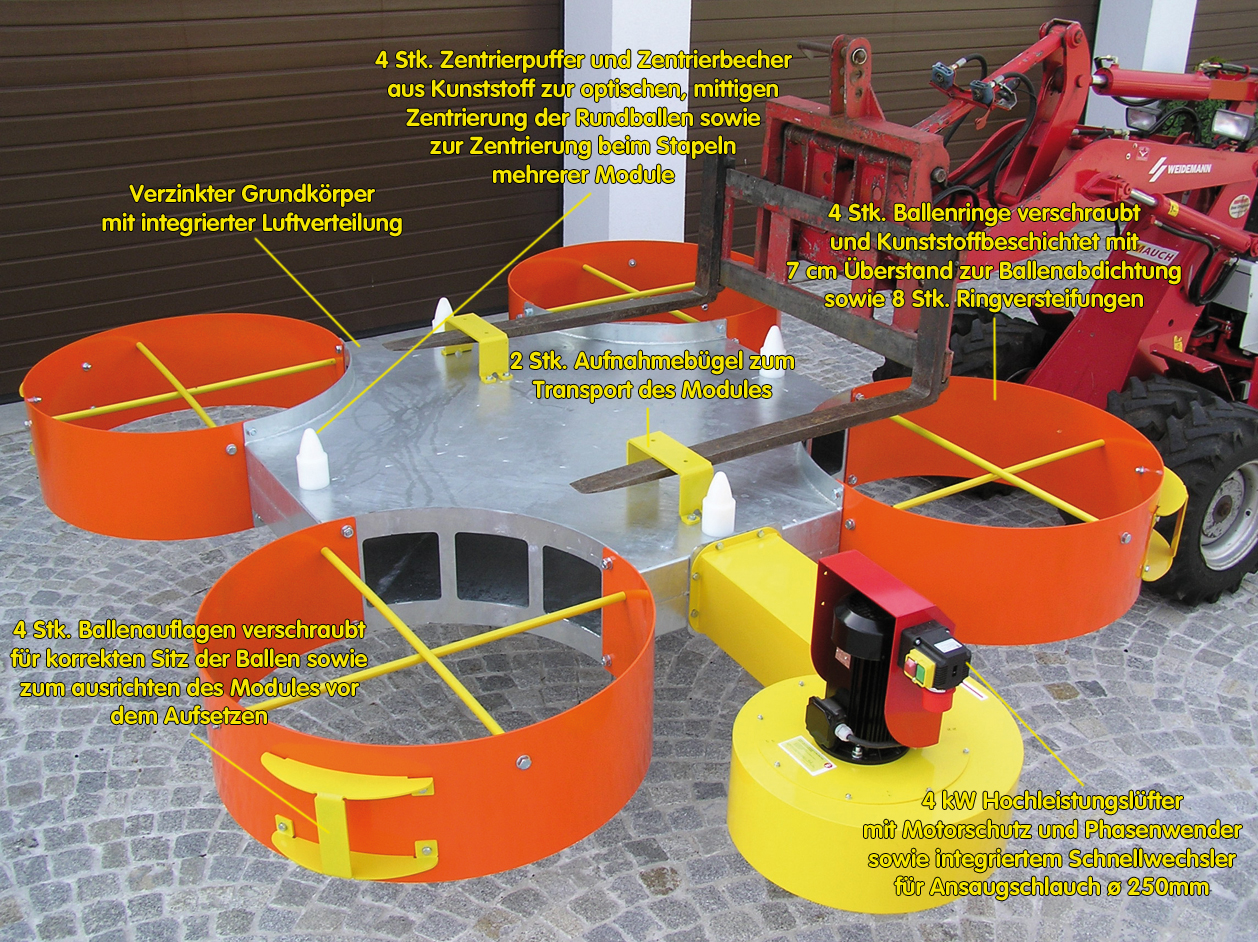

After intensive development work, we have succeeded in producing a bale ventilation that meets the requirements of modern agriculture.Especially in difficult economic times, it is important to achieve optimum performance from the basic feed.

An important planning detail was to make the best possible use of the existing building structures in order to avoid expensive new builds or conversions.Compactness and variable system size were the top priority right from the start of the development phase in order to cover the needs of small businesses right through to large-scale operations.

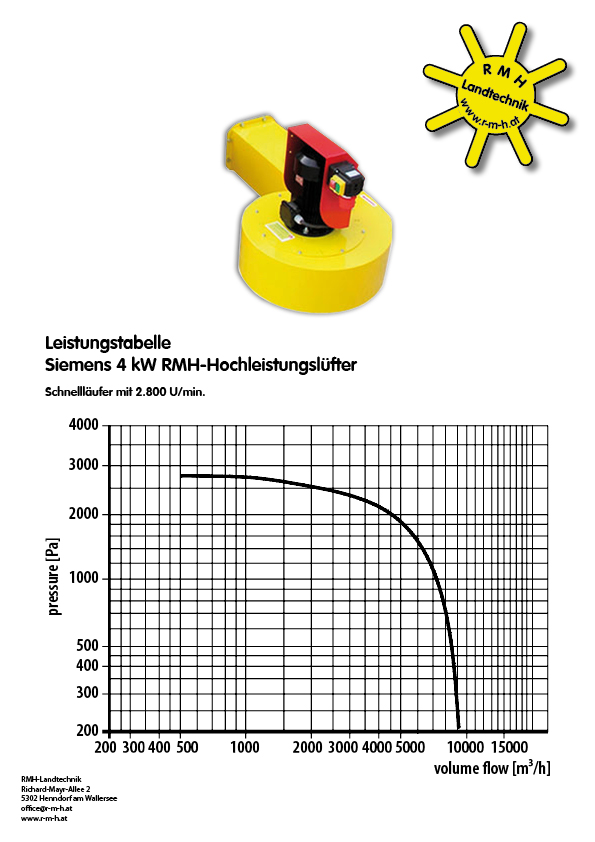

The compact ventilation module has a fixed high-performance fan with 4 kW power and ensures optimum drying results thanks to its high efficiency.

Inside the ventilation module, a flow technician has integrated an air distribution system that ensures even supply of the bales with dry air.The bales and the aeration module can be set up by a tractor with front loader, Hoftrac or a crane system.

To commission the system, only a power cable is needed. The device can also be supplied with preheated or dehumidified air via a quick-change connection.After drying the bales, the modules can be stacked again on a transport frame or a chassis and do not waste space unnecessarily.

The RMH compact ventilation module has already found a great deal of support right from the beginning and has been proving itself for years on farms of all sizes throughout Europe.

-

Model 1410 for bales with diameter 100 - 145 cm

Circle diameter Ø 900 mm

Weight: 385 kg4 kW-Power 10300 m3/h:

263mm WS - 2800 u/minSurface treatment:

Base-Module: Hot-dip galvanized at 470 ° C

Attachments: Plastic coated metal

Model 1710 for bales with diameter 130 - 170 cm

Circle diameter Ø 1050 mm

Weight: 435 kg4 kW-Power 10300 m3/h:

263mm WS - 2800 u/minSurface treatment:

Base-Module: Hot-dip galvanized at 470 ° C

Attachments: Plastic coated metal -

-

How long has the compact ventilation module been?

The first modules were put into operation in 2007. Series production started in 2009.How does this system work?

The device consists of a high-performance fan which was fixedly mounted on a distributor body.

Inside the distribution shaft, a flow engineer has integrated an air distribution, which distributes the drying air evenly across the 4 ventilation rings, thus ensuring uniform ventilation of the 8 bales.What is the advantage of modular construction?

Depending on how many bales should be ventilated, I use one, two, three or more modules and have the advantage of

A) lower power consumption.

B) exactly the required air flow.

C) In the case of smaller quantities of round bales to be dried, less free ventilation rings should be covered.

D) If the ventilation modules are not in use, they can be stacked on each other to save space and do not waste space unnecessarily.What do I have to consider structurally?

If possible, south-facing arrangements have to be placed under a canopy and a 16A / 380V power supply should be accessible nearby or via an extension cable.Do the bottom bales have to be placed on a wooden pallet?

No, but it should be noted that with bales pressed with a fixed chamber press (soft core), the upper bales should be covered with a wooden plate. For bales of a variable press covering is not necessary.Why does the device have a suction hose?

The suction hose is necessary to supply the ventilation with preheated or dehumidified air. It is also possible to use an air preheated via the roof extraction system. When the unit is operated in a hall, it is important that the intake air comes from the outside (if possible, south-facing), otherwise the air in the room will be moved in a circle and there is a risk that the moisture-saturated air will re-enter the bales.Can such a small ventilation fan produce enough air for 8 bales?

This is a high-performance 4kW fan designed as a high-speed fan (2800rpm) especially for our ventilation and with an output of about 10300m3 at a pressure of 245mm water column ensures an excellent ventilation result. The high-performance fan is equipped with a motor protection and a phase inverter.What do I do if I have only 6 or 7 bales to ventilate?

I cover the remaining openings with plastic wrap or tarpaulin and place an already dried bale on top to seal this opening.What should I pay attention to during the ventilation process?

Most importantly, the bale of hay comes to the aeration as soon as possible before the bale reheats and the intake air is checked. In case of heavy rain, the system should only be operated for a short time to cool down the bales, as no drying result is to be expected with moist intake air. A relative humidity of less than 50% is necessary to dry the bales to a residual moisture of less than 16%. However, you have the option to supply the device with preheated or dehumidified air (see on Hompage RMH dehumidifier and RMH air heating).How long takes the ventilation process?

The ventilation time depends on the degree of predrying of the feed stock to be dried (structure, grasses, clover content) as well as the moisture content of the sucked-in drying air. In optimal drying conditions, the ventilation process takes between 12 and 24 hours - a dehumidifier or preheated air has a positive effect on the drying time. It has to be taken into account that the degree of humidity of the intake air is controlled during cold aeration, since with humid air no final drying can occur under 16% residual moisture and thus the bales are not storable.How do I know if the desired degree of drying of hay bales has been achieved?

With a digital hay bale probe (OLLI-Controll or Agreto HFM II) which is also available through us (see accessories).Can I also use such a system jointly?

Due to the compact modular design, this system can also be used jointly, as it is independent of location and can be transported from A to B by means of a transport chassis.

Can I also dry during bad weather?

Yes, in conjunction with RMH dehumidifier or RMH air heating this is quite possible.How long does it take to assemble the system?

The RMH compact ventilation modules are sealed with a double pallet in a foil and can be assembled ready for operation with approx. 40min.

Eine Video Aufbauanleitung finden Sie hier.